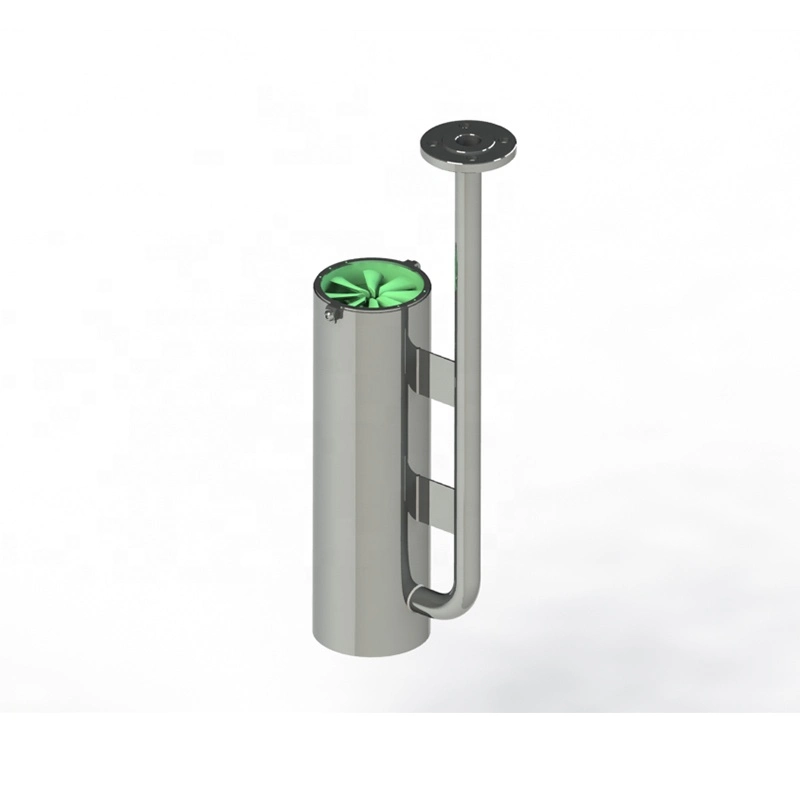

Sewage Treatment Plant Aeration System Swirl Aerator

Overview Product DescriptionQK-XL Swirl Aerator is a stationary diffusing cylinder developed especially for aeration of

Description

Basic Info

| Model NO. | XL-750 |

| After-sales Service | 2 Years Free Spare Parts |

| Warranty | 2 Years |

| Type | Aerators |

| Method | Chemical Treatment |

| Usage | Industrial, Agriculture, Hospital |

| Air Flow | 0.6-0.9 Cubic Meter Per Minute |

| Pressure | 0-1.5kpa |

| Oxygen Capacity | 2.2-3.3 KGO2/H |

| Service Area | 4-12 Square Meter |

| Service Life | More Than 10 Years |

| Mixing Function | Yes |

| Scaling | Not Easy to Scale |

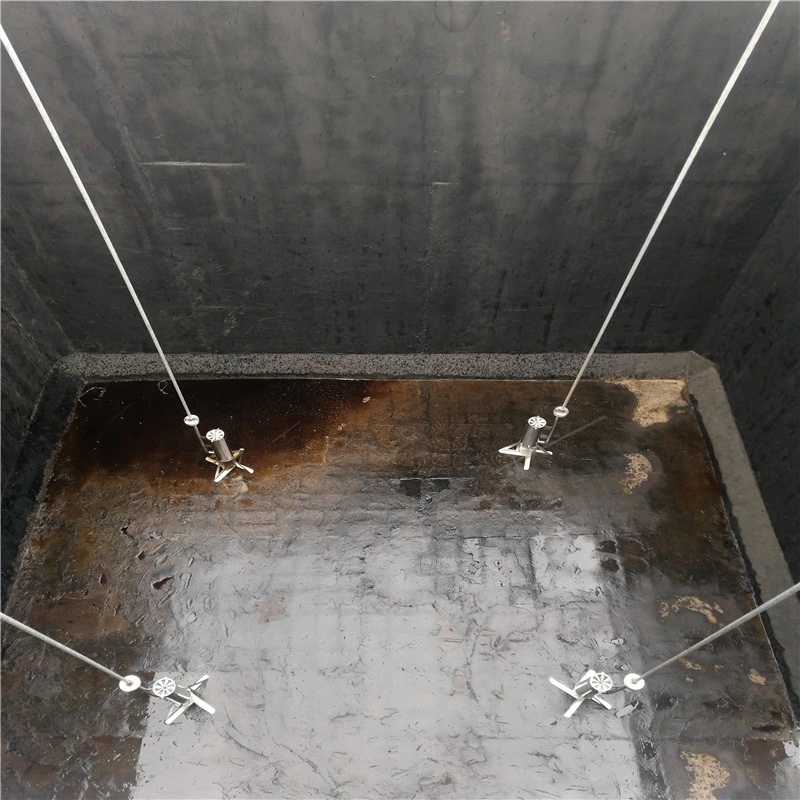

| Easy Installation | Yes, No Need to Empty The Tank |

| Weight | 7kg |

| Dimenstion | 40*20*20cm, 70cm*30*30cm |

| Oxygen Utilization Rate | 22-25% |

| Transport Package | Wooden Case |

| Specification | stainless steel+ PA66 |

| Trademark | Qiankun |

| Origin | China |

| HS Code | 8421219990 |

| Production Capacity | 10000 Pieces Per Year |

Product Description

QK-XL Swirl Aerator is a stationary diffusing cylinder developed especially for aeration of active sludge tank and it has on movable parts. Air blown to bottom passes through the aerator together with water. Then,the air and water are mixed with each other and changed into ultra fine bubbles by stirring them. the bubbles exchange,oxidize,deoxidize,absorb and deaerate the upper and lower fluid materials continuously and efficiently.Application: Active sludge treatment of industrial waste water. Deaeration ofvolatile gas in waste water ,e.g., ammonia, hydrogen sulfide, trihalomethane ,etc. Installed in a reacting chamber for oxidization ,doxidization ,neutralization or reaction acceleleration. Increase of efficiency in exiting electric facility. Purification ofreservoir water. Stirring and mixing of upper and lower fluid materials ofpond ,lake ,etc. Culture of microorganisms in water using aerator s-1 and mixer together. Stirring and mixing of material in brewery. stirring and mixing of sediments in precipitator in human waste treatment plant.Detailed Photos

| XL750 | |

| material | stainless steel 304+PA66 |

| serivice area | 4-12 square meter |

| oxygen capacity | 2.2-3.3 kgO2/h |

| air flow | 0.6-0.9 cubic meter per minute |

Our Contact

Send now